Those shown in the figure above are the twelve sections of the code. 1235 psi 85 Bar Sizing to meet ASME B165 and special flanges Complies with the requirements of FDA21 CFR 1771550.

What Is A Gasket Functions And Types Of Gaskets Used In Piping With Pdf What Is Piping

Division 3 is meant for designing pressure vessels that require internal or external operating at a pressure above 10000 PSI.

. PreliminaryDesignof18inIntegralFlange A 27125 R 3 1 t h M W C 24625 critical section B 16875 g 12 g 1 18 in. They are usually made from carbon steel or stainless steel and assembled from plates by welding. Finally consider spiral wound gaskets a semi-metallic solution that uses one or more V-shaped inserts to centre the ring and add resilience to gasket materials for high-pressure vessels.

Ring-joint gaskets are commonly used in grooved flanges for high-pressure-piping systems and vessels. These joints are not generally pressure-actuated. You should consider the following when designing gaskets.

The recommended values given for the gaskets listed in the code are non-mandatory. They use the pressure in the system to improve the seal. Pressure Vessel Gaskets must handle the elevated steam and hot water temperatures as well as the maximum design pressure of a boiler to create a positive seal.

ASME Boiler and Pressure Vessel Code Calculations. The first gasket design consideration involves determining whether a particular application requires dense or sponge materials. What is a Pressure Vessel.

Of the gasket there is no pressure at the gasket OD and thus no leakage. Corrugated PTFE Gaskets - CPG Advantages. It is recommended that bolt assembly stresses be established with due consideration of the.

Boiler and Pressure Vessel is divided into the following sections. Flange gasket for pressure vessel. Metallic gaskets have good stress capacity property and can seal the pressure.

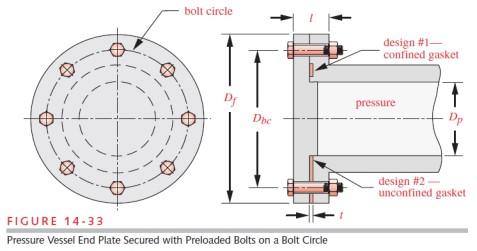

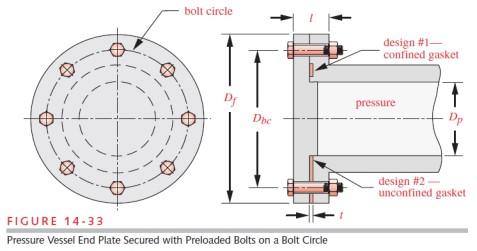

This table gives a list of many commonly used gasket materials and contact facings with suggested design values of m and y that have generally proved satisfactory in actual service when using effective gasket seating width b given in the table following. HOBT ROTT EN 13555. The mating lip on the cylinder closes the recess leaving the gasket completely confined with only a small inside.

You also need to consider closing force specifications in addition to the initial determination. ASME Section VIII in itself consists of three divisions where Division 1 is focused on a design-by-rule approach and Division 2 on design-by-analysis approach. 4 psi creates 100 pounds of force to push that flange into your face.

The current m and y are difficult to replicate for non-asbestos gaskets and do not. For example NAF and metallic gasket. Flange and gasket calculations Lauterbach Verfahrenstechnik GmbH.

Jacketed variants push that principle in a different direction by adding special fillers including graphite to the mix. Be very careful the the flange can not be opened with ANY pressure inside. An over-pressure event refers to any condition which would cause pressure in a vessel or system to increase beyond the specified design pressure or maximum allowable working pressure.

UKL have various types of metallic gasket ranges which can withstand high pressure in the high pressure vessel application. The very important phase to construct a pressure vessel is DESIGN PHASE Design phase is carried out with the care with the help of CODES. While ASME Section VIII Division 1s design-by-rule.

To properly design a pressure vessel it is necessary to understand Section VIII of course and additionally the designer will need to be familiar with Sections II V and IX. G 0 0563 W Design pressure 525 psi Flange design stress 12000 psi Bolt design stress 20000 psi Try 1250 in. In Parr flat gasket closures the gasket is held in a recess in the vessel cover.

Presently for high pressure application metallic gasket is the advance solution which is been used for sealing the pressure vessel. α INTRODUCTION- PRESSURE VESSELS ARE VESSELS WORKING UNDER INTERNAL OR EXTERNAL VACUUM PRESSURE WITH VARIOUS. We recommend using DIN EN 1591.

New gasket constants to replace the ASME Code m and y are currently being developed by the Pressure Vessel Research Council PVRC and ASME. Test information is available for. The values of which ensure the safety performance of vessel.

Their applicable pressure range is from 1000 to 15000 psi. 48 rows Gasket Resources is a full service gasket manufacturer with test labs technical support in-field training and bolted joint failure analysis. These gaskets are designed to give very high gasket pressure with a moderate bolt load.

Self energizing seals would be the best way to go. Cleaver-Brooks has taken great care to insure our factory selected and engineered gaskets perform to to our specifications. The traditional and most popular main head gasket for Parr vessels is a flat gasket made of a PTFE fluoropolymer.

Diameter bolts Root area 0943 sq. Confined and Contained Flat PTFE Gaskets for Temperatures to 350 C. The design values and other details given in this table are suggested only.

A pressure vessel is a closed leak-tight container normally cylindrical or spherical designed to hold fluids ie gases or liquids at a pressure substantially different higher or lower from the ambient pressure. Boiler and Pressure Vessel code contains rules for the design and construction of unfired pressure vessels. The decision as to which standard is to be applied often depends on the end customer.

Various LV modules can be used for the flange gasket bolt calculation varying from a simple rough design to a more complex and precise design. The design of bolted flanges requires that gasket constants referred to as m and y be used in the calculation.

What Are M And Y Gasket Design Constants And How Are They Used Pumps Systems

What Are M And Y Gasket Design Constants And How Are They Used Pumps Systems

Vessel Manways Handholes Pose Special Sealing Challenges

Figure Shows A Pressure Vessel With A Gasketed End Chegg Com

What Are The Best Gaskets For High Pressure Vessels

N 1 15 My 1 5 Os In 2 The Following Pressure Chegg Com

Diagram Of A Typical Reactor Pressure Vessel And Its Sealing Element Download Scientific Diagram

0 comments

Post a Comment